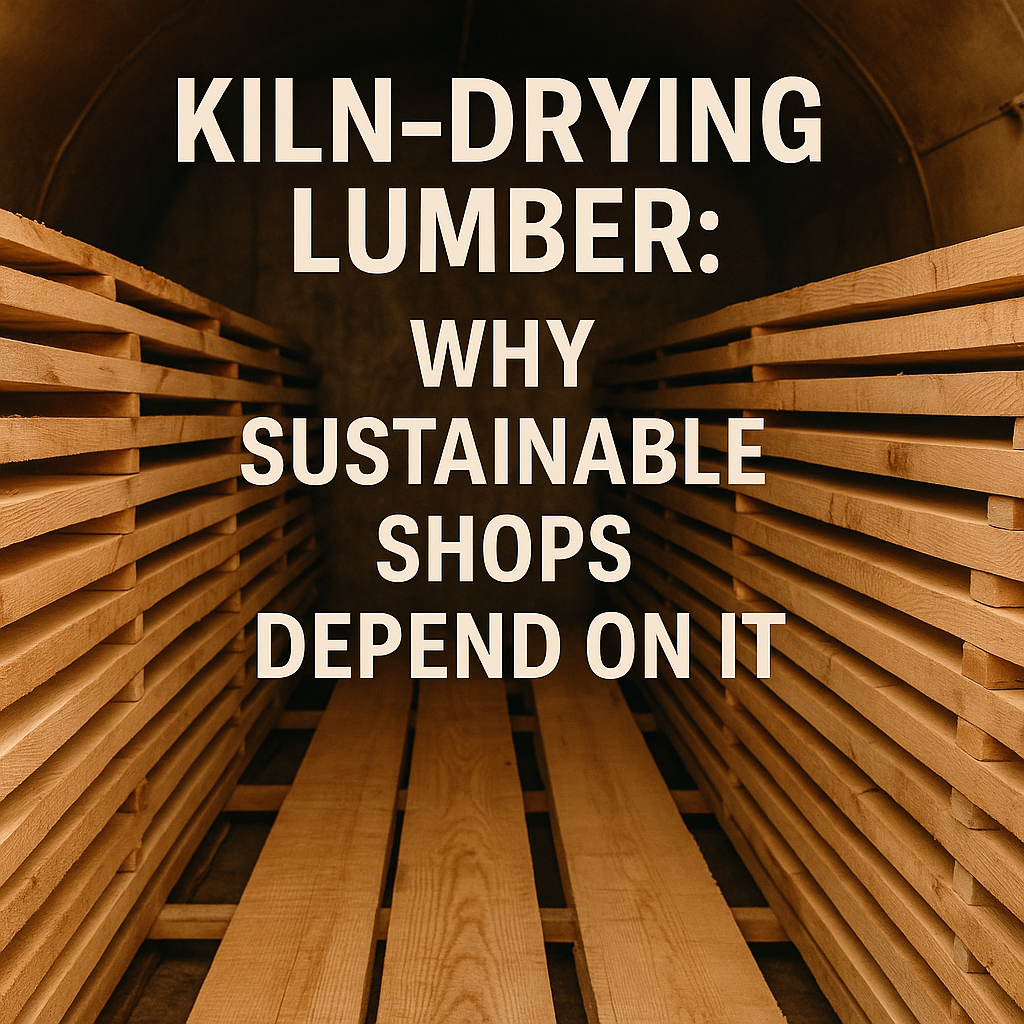

There’s a moment every woodworker knows well—when a rough, raw board finally settles into its true nature. The warping calms. The fibers relax. The grain deepens. And suddenly, you’re holding not just lumber… but potential.

For most modern woodworkers, that transformation happens because of one essential step: kiln-drying.

It isn’t glamorous. It doesn’t smell like fresh wood shavings or look as dramatic as sparks flying off a table saw. But if you want stable, long-lasting, ethically sourced lumber—especially for heirloom pieces—kiln-drying is the quiet hero behind the scenes.

And for sustainable woodworking shops like Hedges Woodcraft, it’s one of the non-negotiables.

Why Moisture Matters More Than Most People Realize

Every piece of lumber starts its life soaked in moisture. Some woods begin at 60–80% moisture content (MC). Even species like walnut, maple, and ash—woods we use every day—start far too wet to work with.

If you cut, plane, shape, or glue wood that still holds too much moisture, the result is predictable:

-

It warps.

-

It splits.

-

It cups or twists.

-

It ruins joinery.

-

And it threatens the longevity of whatever you build.

In other words, too much moisture takes a beautiful idea and turns it into disappointment.

That’s why the entire woodworking world—furniture makers, instrument builders, craftsmen, and hobbyists—depends on one thing: controlling moisture content. And that’s exactly what kiln-drying does with precision and consistency.

What Kiln-Drying Actually Does Inside the Wood

Unlike air-drying, which can take months or even years, kiln-drying uses controlled heat, humidity, and airflow to bring lumber down to a stable, workable moisture content—usually between 6–8% for indoor projects.

Inside the kiln, three transformative things happen:

1. The Cell Walls Harden

Heat changes the structure of the wood’s fibers, making them more predictable and less prone to warping after they leave the shop.

2. Bacteria and Fungi Are Killed

Fresh-cut lumber can harbor mold spores and microbes. The kiln neutralizes them—critical for anyone selling products to customers’ homes.

3. Stress Is Released from the Board

This one matters to us a lot. Wood carries internal tension from the way the tree grew. Kiln schedules are designed not just to dry the lumber but to condition it. That conditioning prevents future twisting and cupping.

That’s why a cutting board, pen blank, or furniture panel made from kiln-dried lumber stays true for years, not just seasons.

Why Sustainable Woodworking Shops Depend on Kiln-Drying

At Hedges Woodcraft, kiln-drying isn’t just a technical step—it’s a sustainability ethic.

1. It Reduces Waste

When a board warps, checks, or splits after milling, you lose usable lumber. Sustainable shops can’t afford to waste good trees.

Kiln-drying dramatically increases the yield from every log. More usable wood means fewer trees harvested.

2. It Supports Local Timber, Not Imported Mass-Produced Lumber

Kiln-drying allows small, local sawmills to produce high-quality lumber that competes with big industrial suppliers. That keeps dollars in the community and reduces the environmental cost of transporting heavy lumber across oceans.

For us, this matters deeply. Many of our pieces—from cutting boards to journal covers—start with lumber harvested and dried right here in Indiana. Those trees have stories tied to our region, and kiln-drying preserves that story without sacrificing stability.

3. It Ensures Long-Term Durability for Heirloom Products

Sustainable woodworking isn’t just about where the wood comes from—it's about the lifespan of what we make.

A kiln-dried cutting board can last decades.

A kiln-dried table can last generations.

What’s more sustainable than building something once and letting it serve for 40 years?

4. It Reduces the Risk of Pests

Air-dried lumber can hide insects in its fibers. Kiln-drying eliminates that risk—critical for any shop shipping products to customers across the country.

Air-Dried vs. Kiln-Dried: Why Many Sustainable Shops Use Both

Air-drying is the old way—peaceful, natural, and gentle. Many woodworkers (myself included) love the look of air-dried walnut or cherry. The color can be deeper, and the grain can feel more relaxed.

But air-drying alone can’t guarantee stability.

That’s why many sustainable sawyers use a hybrid approach:

-

Air-dry the lumber outdoors for months to reduce moisture gradually.

-

Finish the process in the kiln to stabilize the board, kill pests, and bring moisture to a consistent level.

This method reduces energy use while still producing the exceptional stability that today’s woodworkers require.

What Kiln-Drying Means for Hedges Woodcraft Customers

Whether someone buys an ink pen, a cutting board, a tie bar, or a furniture piece from us, kiln-drying is part of the story.

It means:

-

the wood won’t warp on your kitchen counter

-

your journal cover won’t twist in humid rooms

-

your pen won’t crack as the seasons change

-

your table won’t shift during winter or summer

-

the piece inside your home is safe, stable, and sanitized

Kiln-drying is unseen, but never unimportant.

From Tree to Treasure: The Role of the Kiln in the Story of Wood

Every tree we work with has lived through storms, droughts, spring rains, and winter freezes. When that tree finally gives its life for lumber, we owe it respect.

Kiln-drying honors the story of the tree by ensuring its second life—your cutting board, your table, your heirloom pen—is not short-lived.

It’s one of the quiet, faithful processes behind truly sustainable woodworking.

Not flashy. Not dramatic.

But essential.

Because every craftsperson knows:

A well-dried board is the beginning of a well-made piece.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.