If you’ve ever walked through a craft fair or browsed cutting boards online, you’ve probably seen the phrases edge grainand end grain thrown around like everyone should already know what they mean.

But most folks don’t.

And that’s okay.

Truthfully, these two terms might be the single biggest difference between a cutting board that lasts five years…

and one that lasts fifty.

So, let’s pull up a chair, roll up our sleeves, and look at what these phrases mean — and why they matter more than people realize.

First, Let’s Talk About the Grain

Before we define anything, picture a tree.

Straight trunk.

Rings stacking through the years.

Fibers running from root to canopy like thousands of tiny straws.

Those straws are the grain.

Now imagine the board you cut from that tree.

Where you slice the wood determines what the grain looks like — and how the board behaves.

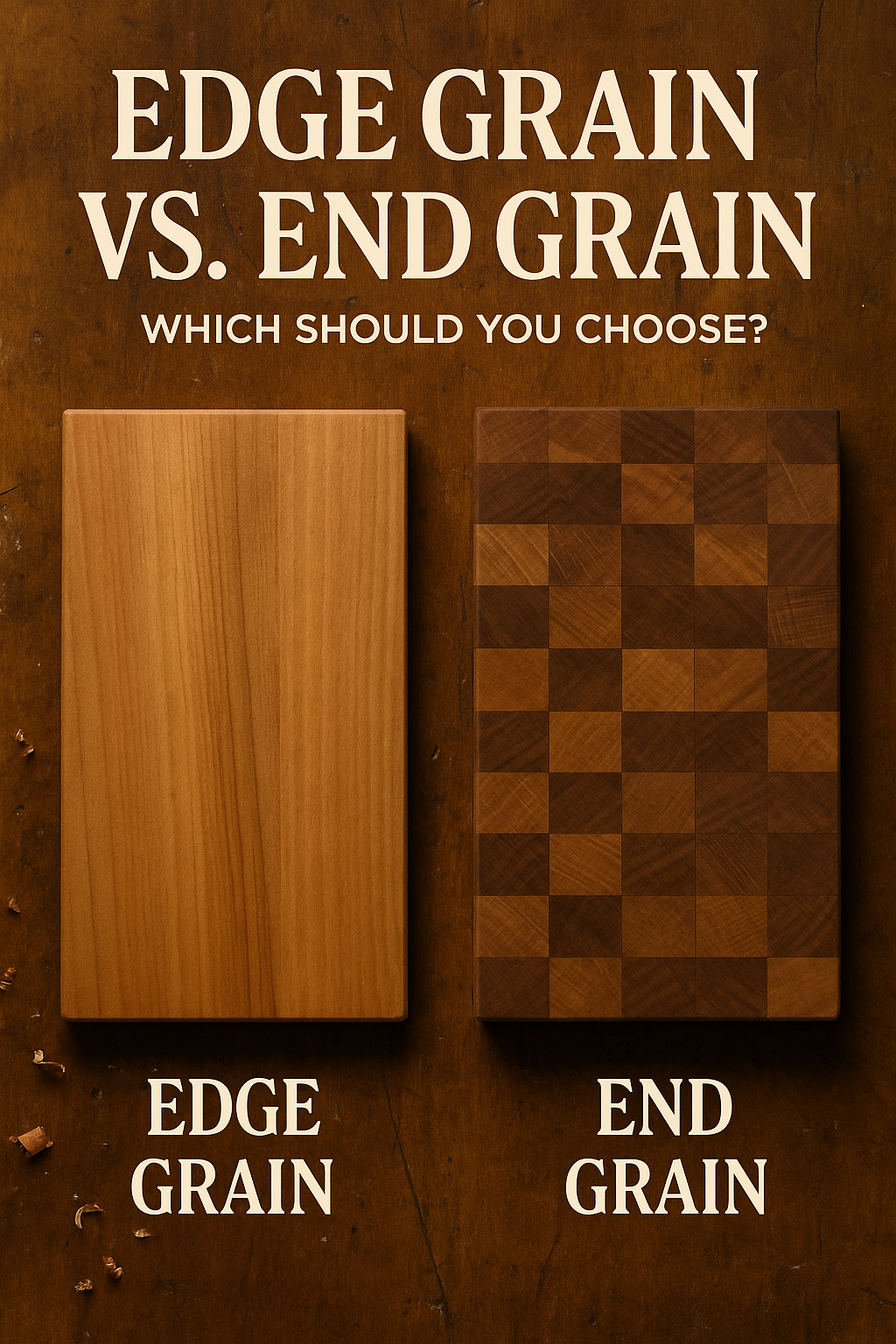

What Is Edge Grain?

Edge grain boards are made by slicing planks from the log, turning those planks on their sides, and gluing them together.

The surface you cut on shows long lines of grain running lengthwise.

Edge Grain Characteristics:

-

Clean, straight lines

-

Smooth, predictable surface

-

Doesn’t dull knives as quickly

-

More resistant to warping

-

Easier to clean and maintain

-

Less expensive than end grain

Think of edge grain as the dependable friend who never overcomplicates things.

It just shows up and does the job well.

If you’ve ever used a classic butcher block countertop, you’ve used edge grain.

What Is End Grain?

End grain is a whole different conversation.

Imagine taking a bundle of straws and slicing straight across them.

You’d see hundreds of tiny circles—that’s what end grain looks like.

End grain boards are made by arranging blocks so that the cut ends of the wood fibers face upward.

This creates that beautiful checkerboard look people love.

End Grain Characteristics:

-

The most durable type of cutting surface

-

Self-healing (fibers close up after the knife leaves)

-

Very gentle on knives

-

Absorbs impacts better

-

More complex to make

-

More expensive (but worth it for serious cooks)

End grain is like the quiet genius of the woodworking world.

It doesn’t brag, but everyone who knows craftsmanship recognizes its value.

Why End Grain Heals Itself

This is where it gets fascinating.

When you cut on edge grain, the blade slices across the fibers.

When you cut on end grain, the blade slips between the fibers.

And after the knife lifts?

Those fibers settle right back into place.

There’s a spiritual metaphor there…

Some wounds cut across us and leave marks.

Others, when handled with grace, close up quietly in time.

Which One Is Better?

Well… “better” depends on what you need.

Choose Edge Grain if you want:

-

A beautiful work surface

-

A dependable, long-lasting board

-

Easier maintenance

-

A more budget-friendly option

Choose End Grain if you want:

-

The absolute best cutting experience

-

Maximum durability

-

A board that will likely outlive you

-

Something truly heirloom-worthy

Both are great.

Both have their purpose.

Both honor the tree well — just in different ways.

The Craftsman’s Perspective

Personally, I love how these two grains reflect two personalities in the woodworking world.

Edge grain is steady.

Reliable.

It does the everyday work faithfully.

End grain is resilient.

Resourceful.

It takes the hits, heals, and is ready for more.

One isn’t better than the other.

They’re simply different expressions of the same tree.

And if that doesn’t sound like the Body of Christ, I don’t know what does.

Reflection Question

Where in your life do you need the steadiness of edge grain or the resilience of end grain—and how might God be shaping you to reflect both?

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.